Anti-Counterfeiting Tape: Revolutionizing Supply Chain Efficiency & Security

In today’s fast-paced global marketplace, businesses face the dual challenge of optimizing supply chain operations while safeguarding products from tampering and counterfeiting. Enter anti-counterfeiting tape —a versatile solution that bridges the gap between operational efficiency and robust security. This innovative tape isn’t just about sealing boxes; it’s a strategic asset designed to streamline workflows, protect brand integrity, and adapt to the complexities of modern logistics. Let’s explore how this technology transforms supply chains, from automated packaging lines to cross-border risk mitigation.

Automating Packaging Lines for Seamless Integration

Modern manufacturing demands speed without sacrificing precision, and anti-counterfeiting tape rises to the occasion. Engineered for compatibility with high-speed dispensers and robotic systems, this tape ensures uninterrupted production cycles. Unlike traditional adhesives that may jam machinery or require manual adjustments, its uniform thickness and advanced adhesive formula minimize downtime. For industries like e-commerce or FMCG, where every second counts, this seamless integration reduces labor costs and boosts throughput. Imagine a packaging line that self-adjusts to varying box sizes, applying tamper-evident seals in milliseconds—this is the reality when anti-counterfeiting tape meets automation.

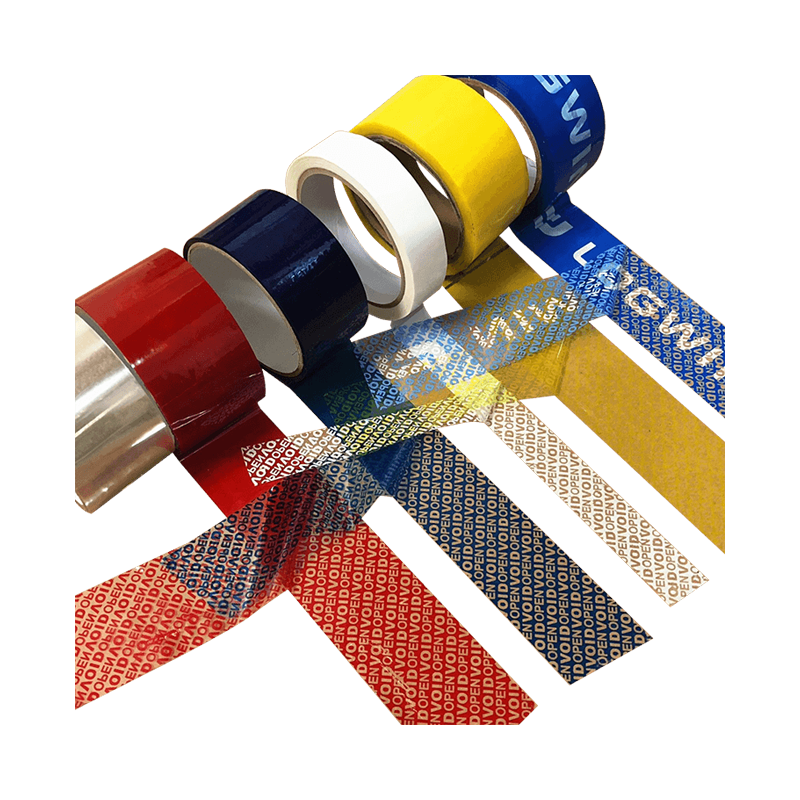

But efficiency isn’t just about speed; it’s about precision. The tape’s customizable widths (4.5cm to 10cm) cater to diverse packaging dimensions, ensuring a snug fit for everything from fragile electronics to bulk pharmaceuticals. This adaptability eliminates the need for multiple tape types, simplifying inventory management. By reducing material waste and operational hiccups, businesses can allocate resources to innovation rather than troubleshooting.

Mitigating Risks in Global Logistics

When products traverse oceans, warehouses, and last-mile deliveries, the risks of tampering, environmental damage, or regulatory non-compliance multiply. Here, anti-counterfeiting tape proves indispensable. Its reinforced construction resists extreme temperatures, humidity, and rough handling, maintaining structural integrity from factory to consumer. For instance, a shipment of temperature-sensitive vaccines secured with tamper-evident tape can withstand tropical climates without compromising seals, ensuring both safety and compliance with health regulations.

Moreover, the tape’s covert security features—such as UV-reactive prints or serialized codes—act as a silent watchdog. Customs officials or retailers can instantly verify authenticity with a quick scan, deterring counterfeiters attempting to infiltrate legitimate supply chains. In regions prone to gray-market diversion, this transparency builds trust and protects brand reputation. Consider the luxury goods sector: a designer handbag sealed with holographic anti-tampering tape not only deters fraud but also enhances the unboxing experience, turning security into a marketing advantage.

Sustainability Meets Innovation

As sustainability reshapes supply chain strategies, eco-conscious businesses are redefining what anti-counterfeiting tape can achieve. Biodegradable adhesives and recyclable materials now align with circular economy goals, proving that security doesn’t have to come at the planet’s expense. Companies can meet ESG targets while maintaining rigorous anti-counterfeiting standards—a win-win for stakeholders and the environment.

The modern supply chain is a symphony of moving parts, and anti-counterfeiting tape is the unsung conductor. By harmonizing automation, risk mitigation, and sustainability, it empowers businesses to operate faster, smarter, and safer. Whether you’re scaling production or shipping globally, this tape isn’t just a tool—it’s a transformation. Ready to rethink your packaging strategy? Let anti-counterfeiting tape seal the deal for your brand’s future.

prevNo previous article

nextDisposable Catering Supplies Unveiled: Mastering Custom Design Limits for Brand Brilliance

English

English 中文简体

中文简体 Español

Español